March 2023 | 2639 words | 10-minute read

The year was 1867 — just a year before the formation of the Tata group as we know it today. The place was Manchester in the United Kingdom. The speaker was Scottish historian and philosopher Thomas Carlyle. In the audience at the lecture was an Indian, Jamsetji Tata. Unbeknownst to both the speaker and the listener, the event set in motion the transformation of India’s industrial destiny.

Jamsetji, who founded the Tata group in 1868, took to heart Carlyle’s idea that the nation that controls iron, controls gold too, and saw in it the hope of India’s industrial revolution, self-reliance and economic liberation.

Bringing the best to India

Jamsetji was determined to build a steel plant that would compare with the best in the world. He relentlessly pursued that dream, undeterred by the hostile investment environment of colonised India, discriminatory government policies, the complexities of prospecting for steel in barely accessible areas and his own age and failing health.

He travelled around the world to gather the best of knowledge, technology and talent. He carried samples of coal and iron ore from India to Germany and America for experiments on the coking of coal; visited every city or town of consequence that was located in an area rich in coal, iron and limestone deposits; and scouted and convinced the best talent to come to India to bring his dream to fruition.

“More than a century ago, even as the blueprints for an independent India were being drawn, the founders of Tata Steel envisioned creating indigenous capability to produce steel as one of the first steps towards building a nation that is truly independent and self-reliant. Today, as we complete 75 years of our independence, we also find ourselves at a very critical juncture — one where we will be expected to invest more in both economic and social infrastructure, including education, health and vocational skills. This is what will create a more prosperous and equitable India. At Tata Steel, we are committed to the cause of nation building and will continue to partner in India’s journey towards becoming a global powerhouse and a leader in every sense of the word.”—TV Narendran, CEO & MD, Tata Steel

One such expert, CM Weld, later said, “I soon learned that Mr Tata’s plan to manufacture iron and steel was inspired by something far broader and deeper than the mere hope of adding to his fortune. … His great cotton mills at Nagpur had become an important industrial school for Indians. He strongly felt the need for further industrial outlets for the Indian people. And he dreamt of a successful iron and steel works as another great industrial school, and another step towards the industrialisation of his countrymen, which he believed was so necessary for their ultimate national prosperity.”

Though Jamsetji did not live to see his dream, his heirs — son Sir Dorabji Tata and cousin RD Tata — persevered to see it to completion.

A swadeshi enterprise

Tata Steel came into being in 1907 as the Tata Iron and Steel Company (TISCO) and held the distinction of being India's first integrated steel company. It was a truly swadeshi enterprise.

It coincided with a time when the nation was swept up in Lokmanya Tilak’s call for the Swadeshi Movement and was beginning to fight the colonisers in a way that had not been seen since the 1857 mutiny. The Tatas, thus, appealed to the people of India to raise the capital and they responded. The Tata office was besieged from early morning till late at night by an eager crowd of native investors. “Old and young, rich and poor, men and women, they came, offering their mites,” Alex Sahlin, a Tata Steel employee who witnessed the enthusiasm, was documented saying. “And at the end of three weeks, the entire capital required for the construction requirements — £1,630,000 — was secured, every penny contributed by some 8,000 native Indians.”

Years later, Sir Dorabji wrote about how proud he was that such a large sum had been raised from the hidden wealth of India for the industrial development of the country: “It was the first time that the raw materials of India did not go out and return as finished articles to be sold in the country. Above all, it was a purely swadeshi enterprise financed by swadeshi money and managed by swadeshi brains.”

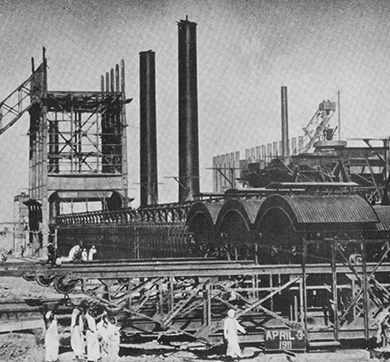

The first ingot of steel rolled out of a 100,000 tonne Tata Steel plant in 1912. The plant attained capacity production by 1916, at the height of World War I, and put up its first expansion programme, the Greater Expansion Scheme, for sanction by the shareholders the same year. The plan was approved.

Tata Steel launched the expansion immediately after the war and had increased production to 420,000 tonnes of saleable steel a year by 1924. By the early 1930s, it was providing 72 percent of India’s requirement of steel, covering the gamut from defence requirements to railway infrastructure, manufacturing industries and iconic projects like the Howrah Bridge. 23,000 tonnes, or about 85 percent of the steel used to build the bridge that defines the Kolkata skyline to this day, came from Jamshedpur.

The company parallelly invested in boosting and leveraging swadeshi intellectual capital. It set up the Jamshedpur Technical Institute in 1921 “to replace foreign technical experts with their Indian counterparts”, the Tata Steel Times noted. It then set up the Research and Control Laboratory in Jamshedpur. This kickstarted the research and development of new types of steel and the launch of brands like TISCROM, TISCOR and Tata Sun — all propelling Tata Steel to become the largest integrated steel plant in the British Empire by 1939 and forever changing the way Indian steel was viewed on the global stage.

Building India's first industrial city

In a letter to Sir Dorabji Tata in 1902, Jamsetji Tata shared his vision for a steel city: “Be sure to lay wide streets planted with shady trees, every other of a quick growing variety. Be sure that there is plenty of space for lawns and gardens. Reserve large areas for football, hockey, and parks. Earmark areas for Hindu temples, Mohammedan mosques, and Christian churches.”

The Tatas were not only building an industry but also creating India’s first planned and industrial city out of a village in the wilderness called Sakchi.

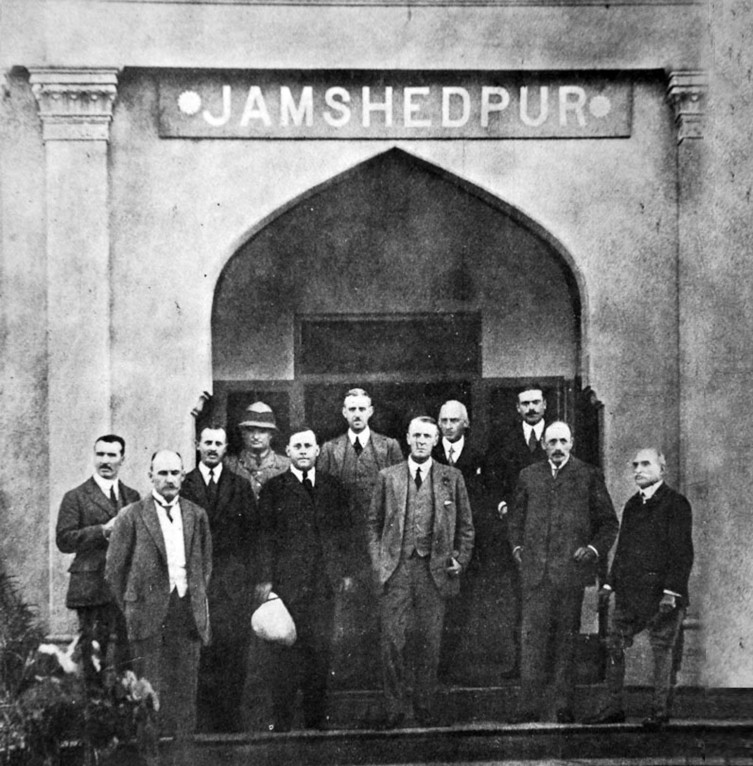

The original town was planned by Julian Kennedy, who had come from the United States to India with Jamsetji. But the Tatas continued to modernise the township, which was renamed as Jamshedpur in 1919. Colonel Frederick Charles Temple, a British engineer who was roped in as an architect, brought in concepts of the garden city and industrial township from the then newly designed British city of Letchworth. In the 1930s, Major PGW Stokes, who had restored Quetta after the 1934 earthquake, came to refurbish it, followed by Otto Koenigsberger, the German chief architect of Mysore.

Today, in line with Jamsetji’s vision, the residents of Jamshedpur live with access to smart-city initiatives, effective and affordable healthcare, quality education, world-class sporting facilities, public spaces and greenery — all administered by Tata Steel.

Steeled by Gandhiji and Netaji

Such was the importance of Tata Steel to India’s economy and future that it had the support of some of the biggest leaders of India’s freedom struggle — Mahatma Gandhi, Pandit Jawaharlal Nehru, Netaji Subhas Chandra Bose and Rajendra Prasad. When labour problems arose with the Tata Steel workers’ union in the 1920s, Gandhiji himself visited Jamshedpur to resolve the issues.

Addressing an audience of 20,000, he had said, “It was my ambition to see one of the greatest — if not the greatest — Indian enterprises in India and study the conditions of work there. But none of my activities is one-sided, and as my religion begins and ends with truth and non-violence, my identification with labour does not conflict with my friendship with capital. And believe me, throughout my public service of 35 years, though I have been obliged to range myself seemingly against capital… in all humility, I may say that I have come here also as a friend of the capitalists — a friend of the Tatas.”

He had added, “I wish to this great Indian firm all the prosperity that it deserves and to this great enterprise every success.”

Steel for a new nation

The making of steel, a key ingredient in agriculture, industry and infrastructure, is closely linked to the economic development of a country. When India gained independence in 1947, it needed an agricultural as well as industrial revolution. Steel was essential to building factories, dams, power plants and other infrastructure. It was essential to manufacturing agricultural tools. It was also essential to scaling down the import of capital goods — needed to industrialise India. As the largest steel maker in the country then, Tata Steel played a key role in the Herculean task of nation building that lay before Indians.

The era of planned large-scale industrial and infrastructure development commenced in 1951 with successive Five-Year Plans. The steel for these plans — which included iconic projects like the Bhakra-Nangal Dam, power plants, heavy engineering industries, railways and other transportation, entire cities like Chandigarh and more — came from Jamshedpur.

The company simultaneously launched a 2MnT expansion programme in 1955 to meet the growing needs of the newly independent country. And when the government decided to build three public sector integrated steel plants in 1956 to produce enough steel to maintain the tempo of economic progress, Tata Steel contributed to the setting up of these plants by helping train engineers and technicians.

"At Tata Steel, we are committed to the cause of nation building and will continue to partner in India’s journey towards becoming a global powerhouse and a leader in every sense of the word.” —TV Narendran, CEO & MD, Tata Steel

Pandit Nehru, the then Prime Minister of India, acknowledged these contributions when he travelled to Jamshedpur to mark Tata Steel’s golden jubilee in 1957. “When you have to give the lead in action, in ideas — a lead that does not fit in with the very climate of opinion, that is true courage, physical or mental or spiritual, call it what you like — and it is this type of courage and vision that Jamsetji Tata showed. …We have our planning commissions, but Jamsetji Tata formed himself into some kind of a planning commission and began his own not a five-year but a much bigger plan,” he said.

In the decades that followed, Tata Steel continued to set the benchmark for the Indian steel industry, so much so that “in 1971, when the coal industry was nationalised, the then minister… left the mines of the company untouched because he wanted nationalised units to ‘sharpen’ themselves against the more efficiently run Tata collieries,” RM Lala noted in The Creation of Wealth.

Setting workplace standards

Tata Steel has been a pioneer in employee welfare schemes and community initiatives, even before legislation mandated them. These include the eight-hour workday, leave with pay, workers’ provident fund scheme — all of which were later adopted by the International Labour Organization and enacted by the law in India.

The company’s people-first approach continues to translate to milestones such as 90+ years of industrial harmony and industry-first initiatives like menstrual leave and equal benefits for LGBTQ+ employees.

Tata Steel is also the first company in India to deploy women in all shifts in mines, and the first Indian company to open core mining operations to the transgender community.

Steel for a liberalised India

The next big leap in the nation’s industrial development came in 1991 when the government liberalised the economy. It was a turning point for Tata Steel too.

Unshackled from the earlier trade controls and restrictions, and anticipating the needs of the now liberalised country, the company embarked on a series of modernisation and restructuring initiatives. Primary among these was the inauguration of the Cold Rolling Mill in Jamshedpur, which equipped the company to meet demands from an even wider range of industries.

Within a decade of liberalisation, it was ranked No 1 in the league table of world-class steel companies by World Steel Dynamics. By 2007, the company that was once the largest integrated steel plant in the British Empire had put the Indian steel industry back on the world map by acquiring Corus, then Europe’s second largest steel producer.

Capacity building

India’s steel consumption has been on a year-on-year sharp growth trajectory and, according to the Indian Brand Equity Foundation, the country’s finished steel consumption is anticipated to increase from 133.596MnT in FY22 to 230MnT by FY31. Over the last few years, Tata Steel has steadily expanded its capacity to serve this need:

- In 2016, it opened its greenfield plant in Kalinganagar with a 3MnTPA capacity. A capacity expansion to 8MnTPA is underway.

- In 2018, the company acquired Bhushan Steel with a nameplate capacity of 5.6MnTPA and a diversified portfolio of high-end products like cold rolled coils, galvanised and colour-coated steel, tubes, and large diameter pipes.

- In 2019, they acquired the steel business of Usha Martin Ltd with specialised ~1.0MnTPA alloy-based manufacturing capacity in long products.

- Earlier this year, the company completed the acquisition of Neelachal Ispat Nigam Ltd. They expect to ramp-up to its rated billet making capacity of 1.1MnTPA within 12 months.

- The company’s flagship facility in Jamshedpur has meanwhile grown to 11MnTPA.

- In FY22, Tata Steel’s operational capacity in India stood at 20.6MnTPA; the company aims to double its capacity in this decade.

Strengthening today, making tomorrow

Today, 110 years since its first ingot of steel rolled out, Tata Steel has come a long way, but its pivotal role in nation building hasn’t changed. The company’s portfolio of products and brands has rapidly expanded across market segments like automotive, construction, industrial and general engineering and agriculture to address diverse needs.

More than a third of infrastructure projects in India now use Tata steel. The company has helped build at least 40 major airports and almost all metro rail networks, partnering the nation to meet the demand of commuters poised to increase multifold. It is in two-thirds of the country’s flyovers and bridges, including landmark ones like Mumbai’s Bandra-Worli Sea Link and Assam’s Bogibeel Bridge. It plays a vital part in powering the nation — from the equipment needed for mining to reinforcing dams that produce hydroelectricity, fortifying solar module mounting structures, constructing power plants and strengthening transmission lines. It has even gone into building sports infrastructure like the Narendra Modi Stadium in Gujarat, which is the world’s largest cricket stadium.

Towards a greener future

Tata Steel has been ranked the World Steel Association Sustainability Champion 2022. Aiding the transition towards a greener future, Tata Steel has deployed industry-leading solutions:

- Commissioned India’s first plant for CO2 capture from blast furnace gas at Jamshedpur

- Conducted a first-of-its-kind trial for continuous injection of coal bed methane in blast furnace to reduce emissions

- Became the first steel producer globally to join the Sea Cargo Charter to reduce Scope 3 emissions in ocean trade and deployed India’s first biofuel-powered ship to transport imported raw materials

- Pioneered the deployment of electric vehicles for transportation of finished steel in India

- Fully commissioned a 0.5MnTPA steel recycling plant at Rohtak, Haryana, which will contribute to conserving valuable resources and reducing landfills as part of its commitment to investing in circular economy

As the world, and with it India, stands poised for the next Industrial Revolution, Tata Steel has once again leaped ahead. In 2019, Tata Steel Kalinganagar became the first Indian manufacturing plant to be recognised as a World Economic Forum Lighthouse, a network that spotlights leaders of the Fourth Industrial Revolution. The Jamshedpur plant earned the same recognition in 2021.

Tata Steel is continuing to invest in technology-led business transformation — to become the leader in digital steel making by 2025 and lead India into Industry 5.0.

—Monali Sarkar

Photographs courtesy Tata Steel Centre for Excellence